Product

- Product series

- Certificates

Information

Danny Jiang

Sales manager

Send an e-mail

Homepage  Product

Product

- Description

- Technical Specifications

- Product Literature

|

Major Technical Specifications |

||||||

|

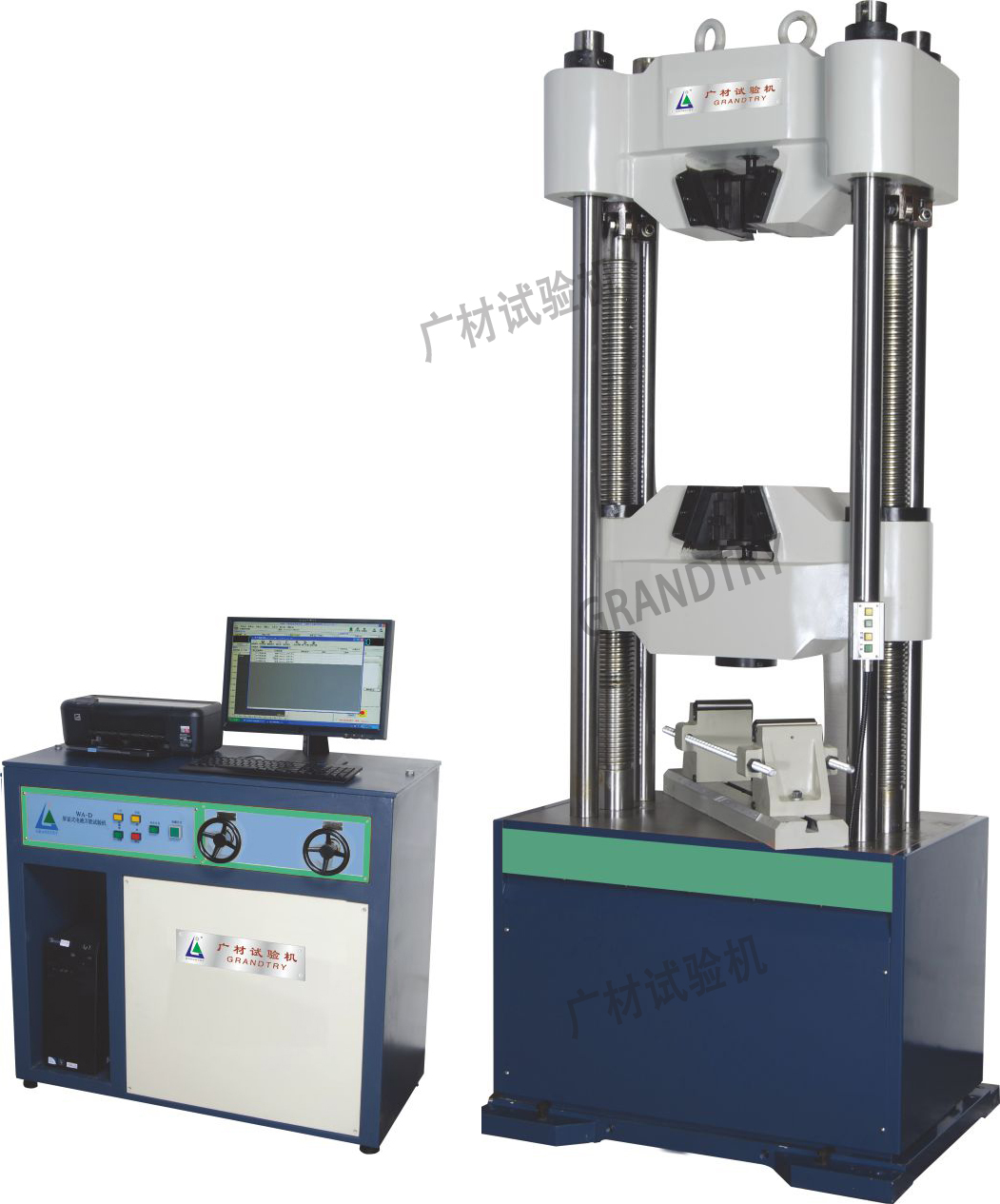

Model and specifications |

WA-100KD |

WA-300KD |

WA-600KD |

WA-1000KD |

||

|

Maximum test force (N) |

100K |

300K |

600K |

1000K |

||

|

Effective measurement range (%) |

1-100 |

|||||

|

Accuracy of force readings (%) |

±1.0 |

|||||

|

Resolution of testing force |

1/200000 |

|||||

|

Maximum piston travel (mm) |

200 |

250 |

||||

|

Control range of stress speed(Mpa/s) |

2-60 |

|||||

|

Speed adjusting range of testing strain(/s) |

0.00025~0.0025 |

|||||

|

Maximum interval between |

630 |

750 |

730 |

950 |

||

|

Maximum distance between |

580 |

650 |

630 |

850 |

||

|

Displacement accuracy (%) |

±1.0 |

|||||

|

Deformation measurement range (mm) |

0-25 |

|||||

|

Accuracy of deformation readings (%) |

≤±1.0 |

|||||

|

Power supply (AC) |

380V/1.5kVA |

380V/2kVA |

||||

|

External dimensions (mm) |

610×560×1780 |

780×600×2100 |

880×650×2260 |

1045×760×2600 |

||

|

Weight (kg) |

700 |

1300 |

1900 |

3000 |

||

Grandtry websites

many countries around the world.

Grandtry always develop new products

in accordance with different market

demands in time.

Explore

Explore

Youtube

Youtube Twitter

Twitter Facebook

Facebook Linkedin

Linkedin RSS

RSS